Inspection Inserts

Now available in a clear, durable plastic that makes inspection less time consuming. The original color is tinted.

Color options: Clear or Tinted.

General information on inserts:

- The clean-out block is required to be able to clean out the mortar droppings that occur when the wall is laid to full height.

- Cleaning out all mortar droppings makes it possible to get a good bond of grout to concrete.

- The holes in the insert relieve the pressure of grout impact, as well as permit leakage for bonding of stucco.

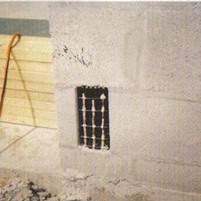

- Inserts are used to act as a form to hold in concrete on high lift concrete block grouted cells.

- The insert is recessed at the finished position to receive plaster or stucco which makes it invisible for painted or stucco walls.

- Inserts are made of a high impact, heat resistant, flexible plastic which prevents them from blowing out when properly installed.

Instructions for use:

Simply install the special hook provided into center hole of insert & maneuver into cut-out block.

- Made for 3 1/2" cut-out block.

- After insert is lined up, pull & twist in all directions to tighten flanges on inside of insert to block.

Insert should be 3/8" recessed at finished position.

- Perforation at top can be broken off if cut-out block is laid too tight.

Watch our videos to show the ease of installation!

Installing

The Pour

Finishing

Before Inspection Inserts

After Inspection Inserts

Inspection Block Marking Template

Just one more way to save money is by making your own inspection blocks. This unique Inspection Block Marking Template is used for marking concrete block to saw to the perfect size & fit for our Inspection Inserts.

Interested in inspection inserts?

Join our 2 million-and-a-half-plus customers so far who know how fantastic Inspection Inserts are! Fill out the contact form or call for pricing! 352-787-5142